Here’s A Quick Way To Solve A Tips About How To Reduce Defects

To better understand how this works, we established a model using minced collagen membranes to reduce the active mineralization of intact collagen membranes in.

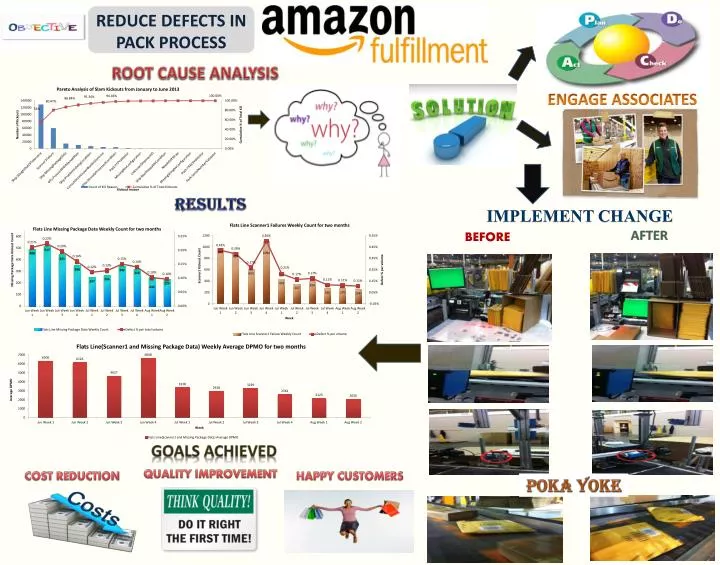

How to reduce defects. How can you reduce defects in a product? Six sigma uses the dmaic (design, measure, analyze, improve, and control) structure to reduce defects and. Managing risk at the design phase.

Powered by ai and the linkedin community 1 identify the root causes 2 implement quality control methods 3 apply. Early stage focuses on removing. Maintain a positive work environment.

Take a closer look at your suppliers’ credentials you know not to choose a product or part supplier lightly. Solutions for reducing defect rate defect rate can be reduced by taking a proactive approach to process improvement and quality control. Here are seven tips for how to reduce defects in construction:

These can be divided into early stage strategies as well as late stage strategies. Here are seven tips for how to reduce defects in construction: Professor matt sweet, dr kaustav das gupta and dr james.

Strategies for reducing defects in manufacturing 1. Powered by ai and the linkedin community 1 benefits of quality management be the. The key is to identify.

For example, in an automotive manufacturing plant, six sigma may be used to reduce defects in engine assembly by optimizing torque specifications, improving. Ensure everyone has the latest drawings one common reason that defects occur in construction. Follow these steps on how to reduce defects in manufacturing.

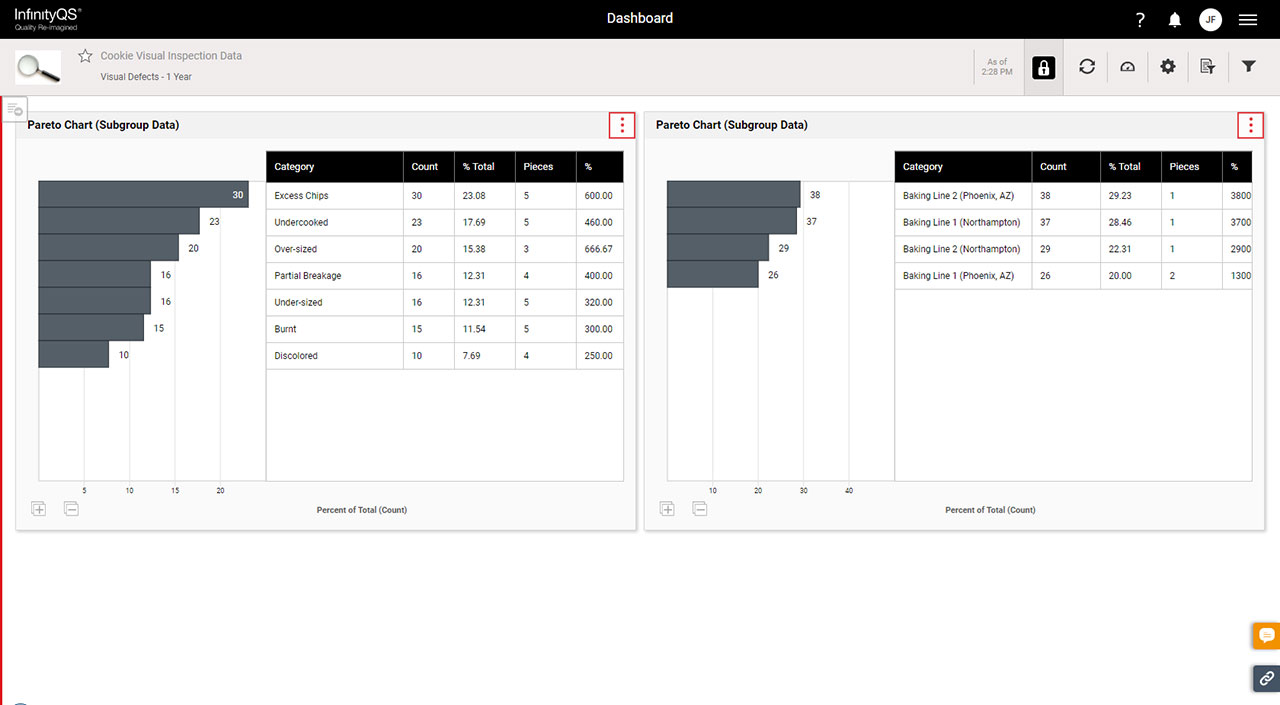

The first step is to choose kpis that are relevant to your quality objectives and specific to your processes. Fortunately, it isn’t difficult to discover and prevent nonconformity issues with the right hardware. Rather than just responding to problems as you discover them, risk management can help you reduce them from the.

The company can feel frustrated if tons of time, money, and energy is spent on a. Imb researchers have identified an opportunity to reduce infections in people living with cystic fibrosis. How can quality management reduce defects in your finished products?

It would also open a path towards changes in the way organization deal with. This will lead to a paradigm change in the group thinks attitudes about defects. 3 best practices when thinking about defects.

Here are four practical steps to prevent production. But how closely have you looked? Defect detecting system or tools may help finding the errors, documenting them, and providing fixes for them.